How to Compare Temperature Humidity Chambers: Key Specs That Matter

Temperature range and control precision

The first question in any chamber selection is the operating range. Typical temperature humidity chambers run from –40 °C to +150 °C, with precision levels varying from ±0.1 °C to ±2 °C. For electronic reliability testing, tighter control (±0.3 °C or better) ensures repeatable stress conditions. In contrast, packaging material conditioning may tolerate wider tolerances.

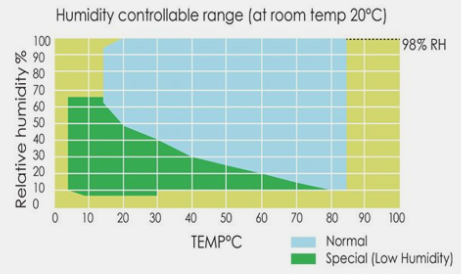

Humidity range and stability

Most chambers operate from 20 % to 98 % RH. Stability is just as important as range—fluctuations above ±3 % RH can cause condensation issues, especially in PCB or battery testing. Desiccant systems or dry-air purging may be required for low-humidity scenarios.

Uniformity and airflow design

Temperature uniformity, often expressed as the maximum deviation across the workspace, directly affects test consistency. A chamber with ±1 °C uniformity at 85 °C/85 % RH is far more reliable than one with ±3 °C, even if both meet the nominal setpoint. Uniform airflow paths and low obstructions inside the test space are critical.

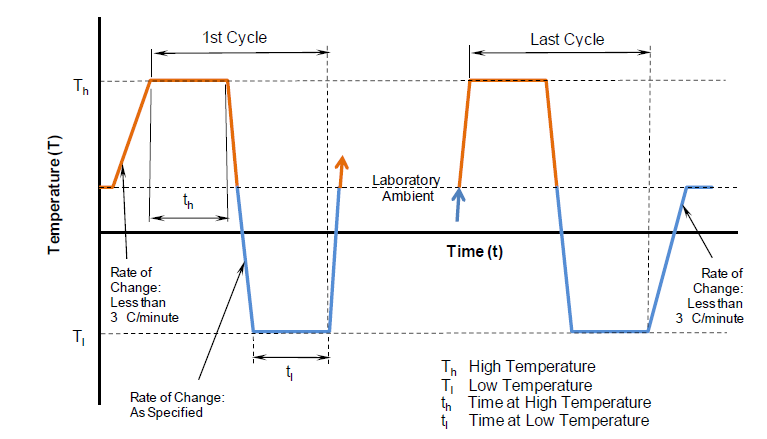

Ramp rate and recovery time

Fast ramp rates—5 °C/min or more—are essential for thermal cycling profiles like IEC 60068‑2‑14. Equally important is recovery time after door openings; a slow recovery can skew time‑sensitive stress tests.

Test standard compliance

Check whether the chamber’s control system allows programming of industry‑specific profiles—such as JESD22‑A104 for thermal cycling, IEC 60068‑2‑78 for damp heat, or ASTM D1776 for textile conditioning.