Quick Troubleshooting Steps

Follow these steps before servicing any components:

Identify the symptom: over-current trip, high-pressure trip, temperature instability.

Locate the component: determine which circuit or protector triggered.

Reset first: Press the reset button on the overload or high-pressure switch.

Inspect deeper: if resetting fails, check fan, motor, or protector condition and replace or repair as needed.

Note: Always de-energize before servicing. If trips persist, contact a qualified technician to inspect refrigerant and system integrity.

Common Faults & Remedies

| # | Fault | Remedy |

|---|---|---|

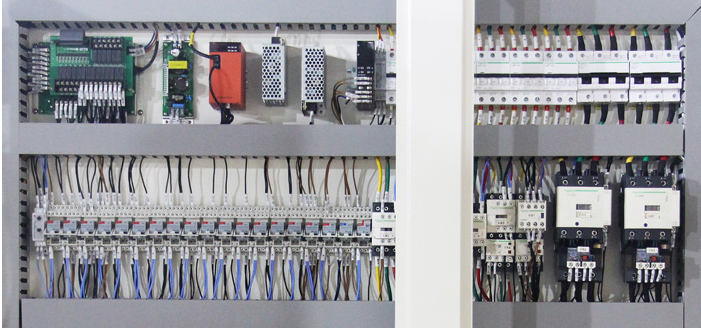

| 1 | First circuit over-current trip | Reset the electromagnetic valve overload protector in the distributionbox. |

| 2 | First circuit high-pressure trip | Remove the lower cover, locate the high-pressure switch, press reset. |

| 3 | Second circuit over-current trip | Reset the second electromagnetic valve overload protector. |

| 4 | Second circuit high-pressure trip | Open cover, locate second high-pressure switch, press reset. |

| 5 | Fan motor failure | Ensure fan spins freely; replace motor if burnt out. |

| 6 | Humidifier over-temp protection | Check protector setting; realign or reset to recommended level. |

| 7 | Power phase error | Confirm correct phase wiring; repair any broken conductors. |

| 8 | Internal over-temperature | Inspect over-temp protector; replace if faulty. |

Technical Insights

Over-current Protection

Prevents compressor damage by cutting power on excessive start-up current. Use soft-starters or clean filters to reduce inrush.

High-pressure Protection

Shuts down the system on excessive condenser pressure. Keep the condenser clean and well-ventilated to maintain proper head pressure.

Temperature & Humidity Control

PT100 sensors and over-temp switches ensure chamber safety. Calibrate sensors every 6–12 months for accuracy.

Phase Sequence & Power Stability

Three-phase motors require correct sequence. Install phase relays to prevent mis-wiring and test interruptions.