- Home

-

Products

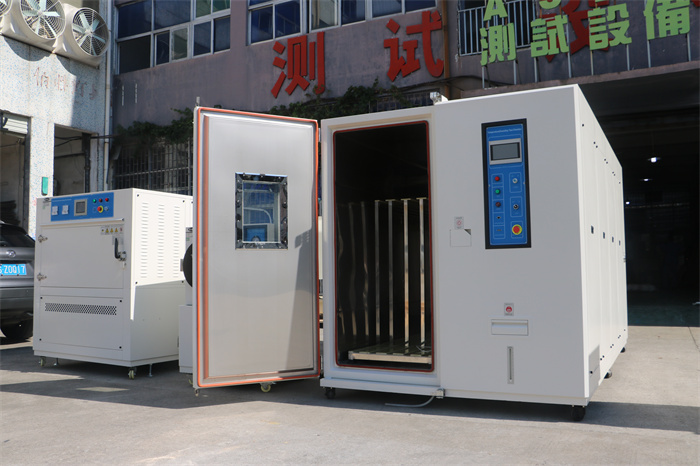

- Temperature Humidity Test Chamber Temperature Cycling Testing

- Vibration Shaker and Simulated Transportation Tester

- Walk in Chamber Temperature Aging Room

- Fast Temperature Humidity Test Chamber

- Temperature Humidity Vibration Combined Test System

- Thermal Shock Test Chamber

- PCT HAST Pressure Aging Test Chamber

- UV Aging Test Chamber Xenon Weathering Chamber

- Solar Panels/UV/Xenon/PV/PID

- Salt Spray Fog/Rain Water Spray/Sand Dust /Drying Oven

- Mechanical Environmental Tester

- About Us

- Application

- Video

- News

- Contact Us