Environmental Test Chamber Temperature Uniformity in Automotive Component Validation

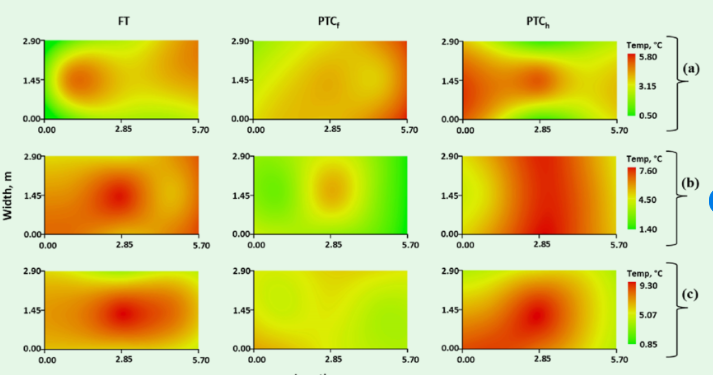

When automotive engineers talk about environmental testing, the conversation often starts with temperature range. Many specifications emphasize extremes: -40°C to +150°C or higher. While maximum and minimum values are important, experience from automotive labs repeatedly shows that Environmental Test Chamber Temperature Uniformity is the factor that more directly determines whether test results are meaningful. In practice, a chamber rated for ±2.0°C uniformity across the test zone ensures that a component sees the same thermal environment at every point, something a wide-range but uneven chamber cannot guarantee.

Consider the testing of a battery pack for an electric vehicle. These packs are large, and even minor temperature gradients inside the chamber can lead to inconsistent state-of-charge measurements, uneven thermal stress, and incorrect safety evaluations. A chamber with wide temperature range but poor airflow distribution may allow the corners to lag behind by several degrees. Over repeated cycles, this translates into misinterpreted degradation rates, misleading predictions for calendar life, and potentially overlooked failure modes. ±2°C uniformity is generally sufficient for industrial-level automotive testing, striking a balance between cost, equipment complexity, and reliable data acquisition.

Plastic interior panels, electronic control units, and under-the-hood modules are similarly sensitive. If temperature uniformity is not maintained, warping, uneven curing, or premature connector fatigue can occur in test samples even when the nominal setpoint is reached. Engineers reviewing such results often find that nonuniform heating, not inadequate maximum temperature, is the root cause. It is a subtle but critical distinction: the test may hit the temperature extremes, but the sample is not uniformly conditioned, which undermines the validity of vibration, humidity, or combined thermal tests.

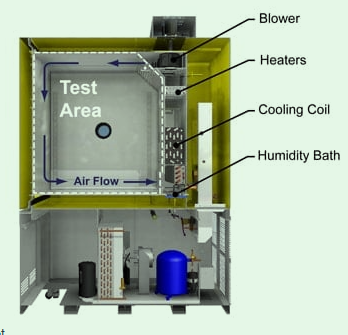

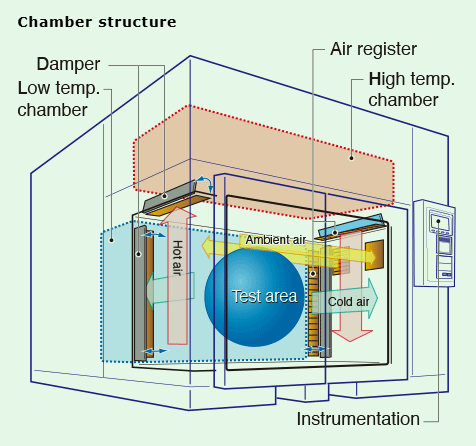

Industrial environmental chambers designed for automotive applications integrate several design features to maintain uniformity. High-capacity ASLI chambers, for example, use optimized airflow ducting, multi-zone fans, and precision PID controllers to achieve ±2°C stability across the chamber volume. Real-world verification often involves placing calibrated thermocouples at multiple points, including corners, upper and lower zones, and near the sample surface. Logging this data over time ensures that the temperature remains consistent throughout long-duration tests, whether simulating cold soak overnight or repeated heat cycles during accelerated aging.

ISO 139 and ASTM D1776 Temperature Humidity Test Chamber for Textile

The measurement of uniformity is just as important as the control itself. ISO 16750 provides guidance on automotive component testing, emphasizing that temperature uniformity should be validated for the chamber’s entire usable volume. Engineers often run initial qualification tests, mapping the internal environment before any actual automotive samples are installed. This baseline allows test profiles to be executed with confidence, reducing the risk of invalid data due to unnoticed gradients.

Another critical point is how uniformity interacts with test cycle duration. Short exposure times may allow some variation to persist, whereas long soak periods enable airflow and thermal inertia to stabilize the chamber environment. For automotive testing, profiles often combine rapid ramp rates with long dwell times to simulate real-world temperature transients. A chamber with proven ±2°C uniformity ensures that all points of the component experience the intended thermal history, which is particularly important for modules containing sensitive semiconductors or hybrid mechanical-electrical assemblies.

Another critical point is how uniformity interacts with test cycle duration. Short exposure times may allow some variation to persist, whereas long soak periods enable airflow and thermal inertia to stabilize the chamber environment. For automotive testing, profiles often combine rapid ramp rates with long dwell times to simulate real-world temperature transients. A chamber with proven ±2°C uniformity ensures that all points of the component experience the intended thermal history, which is particularly important for modules containing sensitive semiconductors or hybrid mechanical-electrical assemblies.

For automotive procurement and certification teams, temperature uniformity is increasingly a primary question. It influences how test plans are written, which chambers are purchased, and which labs are qualified for component validation. Engineers now frequently ask for uniformity maps, multi-point data logs, and verified stability during ramp and dwell phases. While maximum range may still appear in specifications, decision-makers recognize that uneven temperature undermines test reliability. In short, uniformity has become the metric that often trumps maximum range when selecting environmental chambers for serious automotive applications.

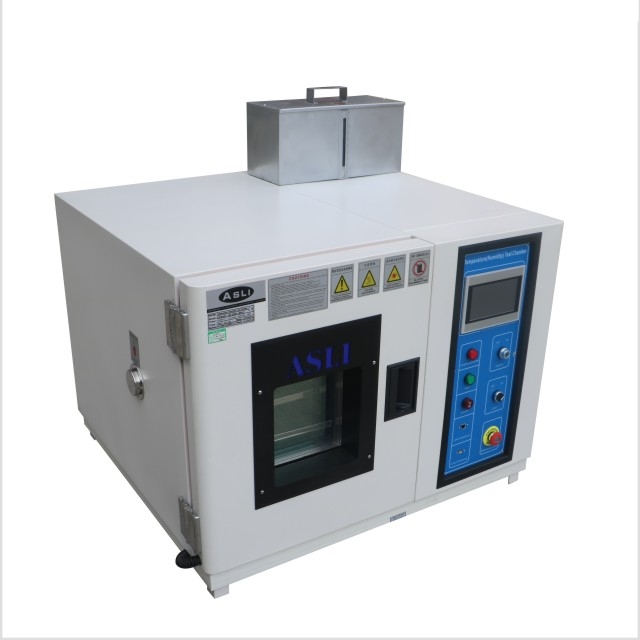

Benchtop Stability Test Climate Chamber – Leading Manufacturers

Finally, considering the evolution of automotive testing, components are becoming more compact, thermally sensitive, and integrated. Electric drivetrains, battery management systems, and advanced driver-assistance modules all require precise thermal conditioning. Chambers that meet ±2°C uniformity deliver confidence not just in passing specifications, but in generating actionable engineering data. As a result, automotive labs now prioritize uniformity verification as a standard part of qualification procedures, and suppliers are increasingly reporting uniformity specifications alongside maximum temperature and range.