Why Temperature Soak Time Is More Important Than Ramp Rate for Reliability Engineers

In environmental testing, two parameters dominate every reliability engineer's discussion: temperature ramp rate and soak time. While both define how thermal stress is applied to a product, they serve very different purposes. Ramp rate determines how fast the temperature changes, while soak time defines how long a sample remains at a given setpoint to reach thermal equilibrium.

Many test specifications—such as IEC 60068, JEDEC JESD22-A104, or MIL-STD-810H—include both variables, yet field data increasingly shows that soak time has a more direct correlation with real-world reliability outcomes. Understanding why is critical to designing test programs that reveal genuine weaknesses rather than artificial failures.

1. The Physics Behind Temperature Soak Time

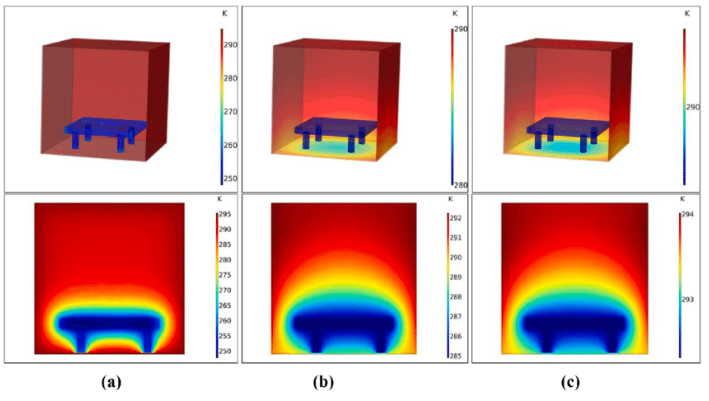

Every component, from a semiconductor die to an assembled battery module, has thermal mass and different heat transfer coefficients. When a chamber reaches the programmed temperature, it doesn’t mean that the entire test sample has.

During the soak phase, heat (or cold) must penetrate the component evenly—through housing materials, PCB layers, adhesives, and encapsulants. If the soak duration is too short, temperature gradients remain inside the product. These gradients can cause:

Uneven expansion and contraction, leading to mechanical stress;

Inaccurate readings of internal temperature sensors;

False negatives in failure analysis, especially in thermal cycling or thermal shock testing.

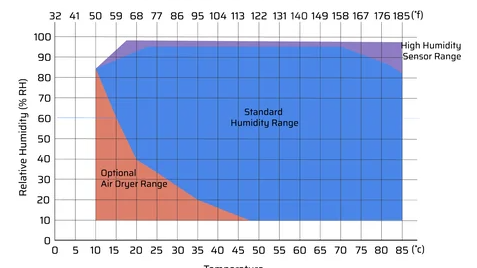

That’s why standards often define “soak” not just as a time value but as a temperature stabilization criterion—for example, maintaining the chamber until the product temperature remains within ±2°C of the setpoint for a defined duration.

2. Ramp Rate: Fast Changes, Fast Failures—but Not Always Realistic

Reliability engineers often prioritize high ramp rates because they accelerate stress testing and shorten total test time. Rapid heating and cooling can indeed expose weak solder joints, delamination, or brittle materials. However, real-world environments rarely exhibit such instantaneous changes.

For example:

Under-hood components in vehicles may experience temperature changes of 5–10°C per minute, not 20°C per minute.

Battery modules inside electric vehicles experience thermal shifts limited by their insulation and heat capacity.

Excessive ramp rates can introduce non-representative failure modes—cracks, seal failures, or thermal fatigue that would never occur under real conditions. For predictive reliability and life estimation, controlled ramp rates combined with appropriate soak times produce far more meaningful data.

3. How Inadequate Soak Time Distorts Test Data

If the soak period is insufficient, engineers risk collecting data that misrepresents true performance. Common examples include:

False pass: The surface reaches the required temperature, but internal layers remain cooler, so internal stress reactions are incomplete.

False fail: Rapid surface heating creates local stress that exceeds material tolerance, leading to cracks that wouldn’t occur during actual operation.

Inconsistent results: Two samples tested in the same chamber may produce different outcomes because thermal equilibrium was never achieved.

In automotive and electronics industries, such data distortion can lead to over-engineering (adding unnecessary cost and weight) or under-engineering (premature field failures). Both outcomes are expensive and damaging to reliability metrics.

4. Defining Optimal Soak Time by Product Category

There is no universal soak duration—it depends on material composition, product size, and thermal properties. Below are typical engineering practices:

| Product Type | Typical Soak Duration | Test Standard Reference |

|---|---|---|

| PCB assemblies | 5–15 minutes after temperature stabilization | JESD22-A104 |

| Lithium-ion battery modules | 30–60 minutes | UN38.3 / IEC 62660 |

| Metal structural parts | 15–30 minutes | MIL-STD-810H, Method 501.7 |

| Sealed enclosures with insulation | 60–120 minutes | IEC 60068-2-14 |

For complex assemblies, engineers often instrument multiple thermocouples inside the product and program the chamber to start timing the soak only after internal temperatures reach setpoint. This ensures that the entire test volume—not just the air—has stabilized.

5. Energy Efficiency and Equipment Considerations

From a test equipment perspective, soak time also affects energy efficiency and chamber utilization.

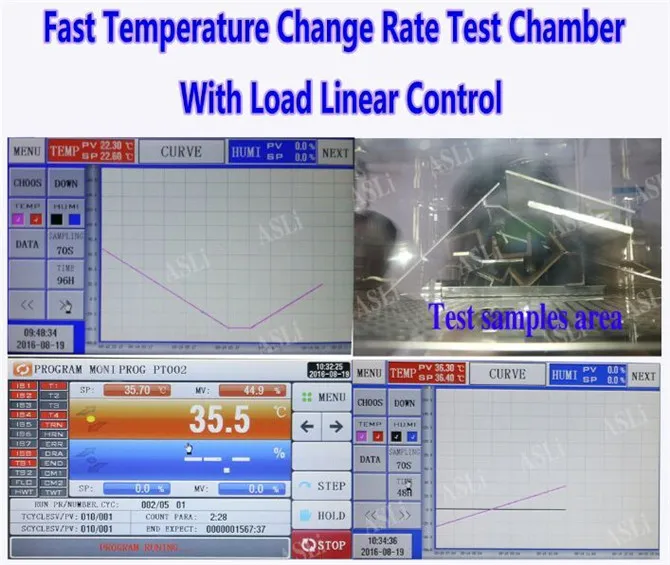

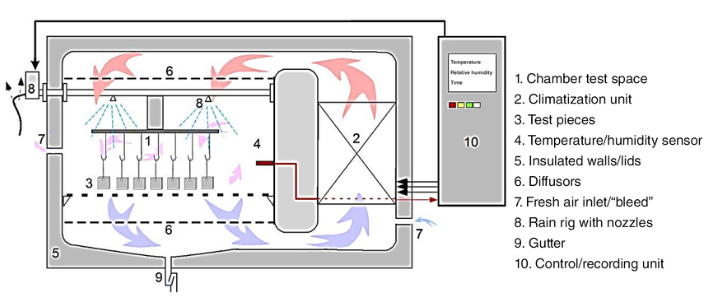

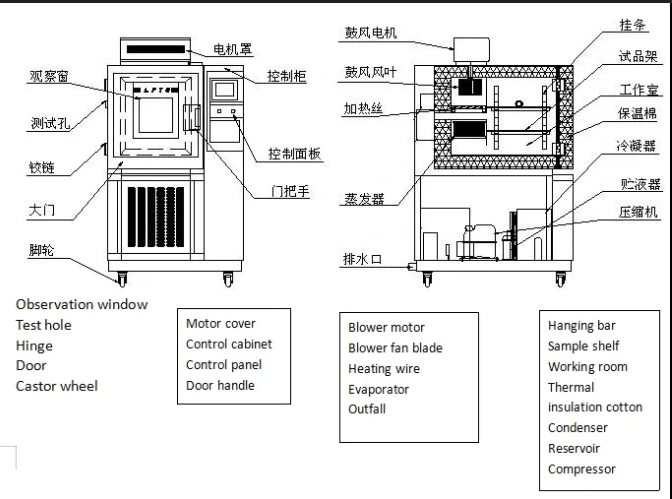

A well-designed chamber with uniform airflow and high heat transfer efficiency can achieve internal temperature balance faster, reducing unnecessary soak duration. Conversely, chambers with poor airflow or large gradients require longer stabilization, wasting energy and extending test cycles.

Thus, optimizing soak time isn’t just about test accuracy—it’s about laboratory throughput and cost efficiency. Reliability engineers should review both chamber uniformity specifications (±2°C or better) and airflow volume rate, especially for dense or high-mass products like battery modules.

6. The Role of Standards and Statistical Validation

Most international testing standards recognize soak time as a controllable variable. For instance:

MIL-STD-810H, Method 520.4: Requires temperature uniformity within ±2°C before initiating dwell.

IEC 60068-2-38: Specifies minimum soak periods depending on sample size.

JEDEC JESD22-A104: Recommends ensuring the temperature of each monitored point remains within ±5°C for the duration of exposure.

Reliability programs often incorporate statistical validation (e.g., Weibull analysis, lognormal failure distribution) to correlate soak duration with failure probability. This quantitative approach confirms whether additional soak time materially improves data repeatability.

7. Real-World Case: EV Battery Thermal Cycling

A battery pack tested under a 10°C/min ramp rate without sufficient soak time showed early degradation in its interconnects during laboratory trials. Post-test diagnostics revealed that while the surface temperature followed the programmed cycle, the cell cores lagged by nearly 12°C.

When engineers increased soak duration from 30 to 60 minutes—allowing full thermal equilibrium—the failure rate dropped by 60%. This validated that temperature non-uniformity, not design weakness, was the true cause of premature degradation.

This case underscores why soak time is not a trivial setting but a critical reliability parameter that ensures stress distribution matches field conditions.

8. Balancing Speed and Accuracy in Modern Test Labs

Modern automotive and electronics labs increasingly adopt adaptive soak algorithms, where data from embedded thermocouples determines when equilibrium is achieved. Instead of fixed soak durations, the system dynamically adjusts dwell time based on measured stabilization rates.

This approach maintains test accuracy while minimizing idle periods—combining statistical reliability with operational efficiency. Integration with data acquisition systems and digital twins further enables engineers to model temperature diffusion and predict stabilization times with high precision.

9. Key Takeaways for Reliability Engineers

Ramp rate ≠ reliability indicator — high speed increases stress but not necessarily realism.

Soak time defines accuracy — it ensures consistent, meaningful temperature exposure.

Optimize with data — instrument products internally to determine when true equilibrium occurs.

Follow standards — reference MIL-STD-810H, JESD22-A104, and IEC 60068 for best practices.

Think holistically — soak duration affects both test quality and lab efficiency.

Ultimately, temperature soak time reflects the maturity of a test program. Reliability engineers who manage it scientifically gain not only accurate failure data but also better insight into real-world product performance. Ramp rate may catch attention—but soak time earns trust.