When research and development (R&D) teams discuss environmental testing today, the conversation increasingly turns to flexibility, not just precision. Traditional full-size environmental chambers occupy valuable floor space, require complex installation, and are often over-specified for small-batch or early-stage experiments. In contrast, modular and portable environmental test systems—including benchtop and vertical-standing chambers—offer a compact yet powerful alternative, enabling laboratories to perform accurate temperature and humidity testing with minimal infrastructure investment.

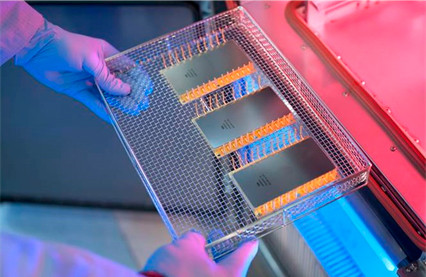

Bench-top Type Temperature(&Humidity) Test chamber

Why Lab Flexibility Matters in Modern R&D

Modern R&D facilities face growing pressure to adapt quickly. Whether it’s a pharmaceutical stability study or an electronic component reliability evaluation, test requirements change as products evolve. Building a fixed test room or dedicating large equipment to one project limits both space and budget flexibility. Portable environmental chambers address this challenge by integrating all necessary control systems, insulation, and data interfaces into a self-contained unit.

For small or shared laboratories, this means:

Fast installation: no permanent ducting or structural modifications required.

Easy relocation: systems can be moved between labs or departments as testing priorities shift.

Reduced downtime: faster commissioning and simplified maintenance cycles.

R&D teams benefit by being able to validate prototypes, packaging, or materials under controlled conditions within hours instead of weeks—critical for industries where time-to-market directly affects competitiveness.

How Modular & Portable Test Chambers Support Compact Labs

Benchtop and modular environmental test chambers combine compact design with the same control precision found in large-scale systems. Using high-efficiency compressors and advanced PID control algorithms, these chambers maintain temperature uniformity within ±2°C and humidity stability within ±3% RH, even during long soak or cycling conditions.

This performance level enables them to support a wide range of small-scale testing applications:

Material qualification for polymer, adhesive, or coating samples

Component durability testing for circuit boards or sensors

Accelerated aging of packaging materials or medical devices

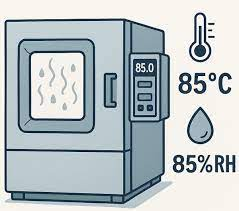

Pharmaceutical stability testing under ICH conditions (e.g., 25°C/60% RH, 40°C/75% RH)

In modular systems, the chamber body, control unit, and humidity module can be separated or combined as needed. For example, a basic temperature-only chamber can later be upgraded with a humidity module or integrated into a multi-chamber rack for parallel testing. This modularity aligns perfectly with R&D workflows that evolve over time and need scalable infrastructure without the cost of full system replacement.

Small Size Vertical Floor stand Laboratory Comfortable operation Test Chambers

Pharmaceutical and Small Electronics Use Cases

Pharmaceutical applications represent one of the most active areas for benchtop chamber adoption. Under ICH Q1A (R2) and WHO stability guidelines, drug samples must be stored under precise conditions for extended periods. Portable temperature and humidity chambers allow manufacturers to start long-term and accelerated stability studies within limited laboratory space, without waiting for central validation room availability.

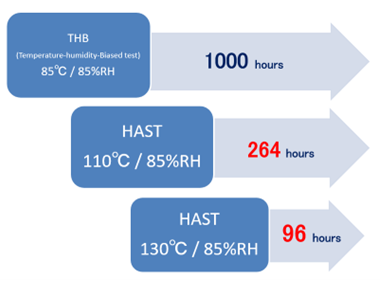

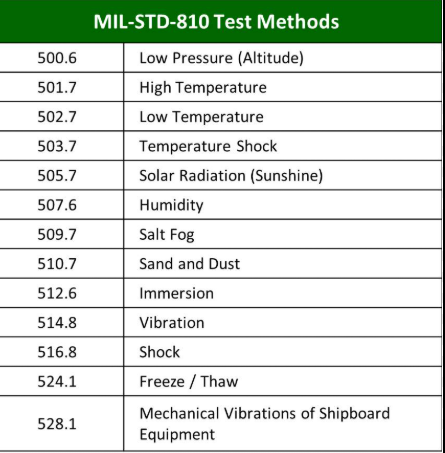

For electronic and semiconductor laboratories, compact environmental chambers enable early reliability screening and solder joint stress testing. Engineers can replicate thermal cycling and humidity exposure according to IEC 60068-2-38 or MIL-STD-810G protocols, even in confined bench environments. Because small test volumes achieve temperature equilibrium faster, test cycles complete more quickly, improving data turnaround and allowing for more iterative testing.

Moreover, industries such as automotive sensor development and battery component R&D now use portable systems for pre-validation work before moving to larger-scale qualification. This reduces the burden on the main validation labs and ensures that only optimized designs reach the final certification stage.

Technical Considerations: Precision, Validation, and Cost Efficiency

While modular and portable systems provide flexibility, they must still meet stringent accuracy and safety requirements. A well-designed benchtop chamber typically includes:

Uniform airflow distribution using multi-zone fans to eliminate hot or cold spots

PID-based digital control for tight temperature and humidity regulation

Real-time data logging with USB or Ethernet interfaces for traceability

Safety features such as over-temperature protection and power failure recovery

These features ensure compliance with international testing standards like ISO 17025, ASTM D4332, and IEC 60068. For laboratories pursuing accreditation or preparing data for regulatory submission, the availability of calibration certificates and detailed uniformity mapping is essential.

From a cost perspective, portable systems also deliver measurable savings. They consume less energy due to smaller chamber volumes, require no permanent foundation, and can be maintained by in-house technical staff. Many models operate on standard electrical supplies (220–240V single-phase), avoiding the need for industrial wiring or dedicated cooling water lines.

The Future of Modular Environmental Testing

The growing emphasis on sustainability and rapid innovation continues to favor modular systems. Researchers increasingly seek equipment that can be reconfigured, reused, or repurposed across different projects. In addition, digital control platforms are now integrating remote monitoring, cloud-based data logging, and predictive maintenance algorithms—making even compact chambers part of a larger smart-lab ecosystem.

For pharmaceutical firms, this means real-time condition tracking across multiple stability units worldwide. For electronics and materials engineers, it enables automatic notification when parameters drift beyond tolerance. As R&D moves toward automation and data-driven validation, portable environmental test chambers are no longer secondary tools—they are becoming core instruments in agile laboratory infrastructure.

The evolution of modular and portable environmental test systems reflects a broader shift in how laboratories approach precision testing. Compact chambers now deliver the same performance once limited to large walk-in units, with greater efficiency and flexibility. For pharmaceutical stability studies, electronics reliability screening, or materials research, these systems bridge the gap between speed and accuracy. They enable engineers to focus less on logistics and more on generating reliable data—a fundamental step toward faster, smarter innovation.