HOW TO CHOOSE THE RIGHT TEMPERATURE AND HUMIDITY TEST CHAMBER? 5 KEY FACTORS YOU MUST KNOW

Choosing the right temperature and humidity test chamber can be confusing. Common questions include:

- "What range do I really need?"

- "How accurate does the control system need to be?"

- "Will this chamber support my product tests properly?"

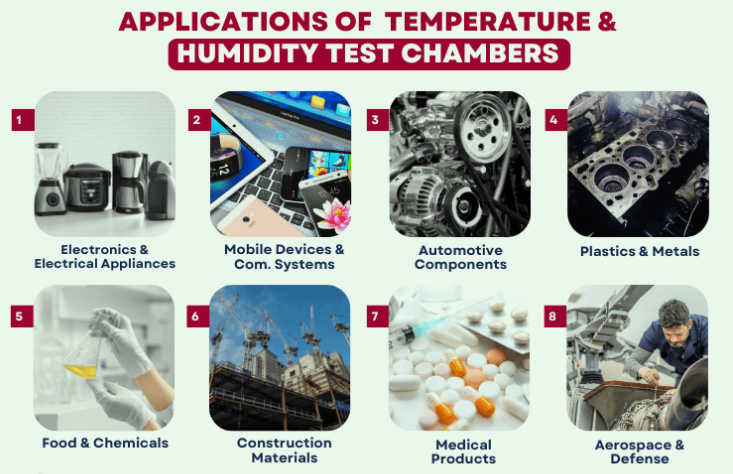

This guide will help you make the right decision without overpaying. Whether you're testing electronics, automotive parts, or pharmaceuticals, remember: the best chamber is not the most expensive, but the one that fits your real needs.

1. KNOW YOUR INDUSTRY STANDARDS & TEST REQUIREMENTS

Each industry follows specific testing protocols. For example:

Automotive Parts: -40°C to +100°C, humidity from 10%RH to 95%RH

Battery Testing: Often requires extreme temperatures and safety features

Pharmaceutical Packaging: Demands stable humidity and long-term consistency

Electronics/Chips: Focus on temperature change rate and uniformity

TIP: Make sure your tests comply with ISO, IEC, GB, MIL, or other relevant standards.

2. TEMPERATURE & HUMIDITY RANGE

Define your minimum/maximum temperature and humidity needs, plus change rate.

| Parameter | Common Specs |

|---|---|

| Temp Range | -40°C to +150°C (some up to -70°C or +180°C) |

| Humidity Range | 20~98%RH (some down to 10%RH) |

| Temp Change Rate | Recommended ≥ 3°C/min for rapid test needs |

NOTE: Don’t overestimate your needs. Bigger ranges mean higher cost and power consumption.

3. INTERNAL SIZE & SAMPLE LOADING

- Leave at least 30% extra space for airflow and temperature/humidity balance.

- Heavy or large samples? Check loading capacity and shelf design.

- Plan the layout if testing multiple samples to avoid uneven conditions.

TIP: Ask the manufacturer to help check if the size suits your samples.

4. CONTROLLER SYSTEM & DATA LOGGING

Modern chambers offer smart control features. Things to consider:

Controller Brand: Japan UNICON, RKC, or custom system

Data Export: USB, SD card, or Ethernet support; Excel compatibility

Remote Access: Web/mobile monitoring, alarms, and cloud control

Programmable Cycles: Multi-segment programs, loops, curve editing

5. AFTER-SALES SUPPORT & RELIABILITY

Don’t overlook service and support, especially for international shipments:

Is there remote or local technical support?

Is the interface multilingual?

Are spare parts easy to get?

Are certifications like CE included for export?

A cheap machine without reliable support = expensive downtime later.

FINAL THOUGHTS

Choosing a chamber doesn’t have to be hard. Focus on:

Your test goals

Required temp/humidity range

Sample space and layout

System functionality

After-sales reliability

Let the professionals do the rest. Contact ASLI today for tailored solutions.