How to Maintain a Humidity Test Chamber in Tropical Climates: Southeast Asia Guide

Maintaining a humidity test chamber in hot, humid regions like Southeast Asia (Singapore, Malaysia, Indonesia, Vietnam) requires special attention to ensure accurate and long-lasting operation. Here's how you can protect your equipment and avoid unexpected failures.

Why Tropical Climates Matter

High humidity and constant heat accelerate condensation, sensor drift, and mineral scaling—key reasons for frequent chamber malfunctions in tropical regions.

Top 5 Maintenance Tips

Use distilled or deionized water to prevent mineral buildup in the steam generator and water pipes.

Clean the water tank and humidity sensor every 2 weeks to avoid bacteria, mold, or algae growth.

Calibrate the humidity sensor especially after rainy seasons (Oct–Mar).

Replace air filters quarterly to maintain airflow and prevent dust clogging.

Drain excess condensate regularly to reduce internal corrosion risk.

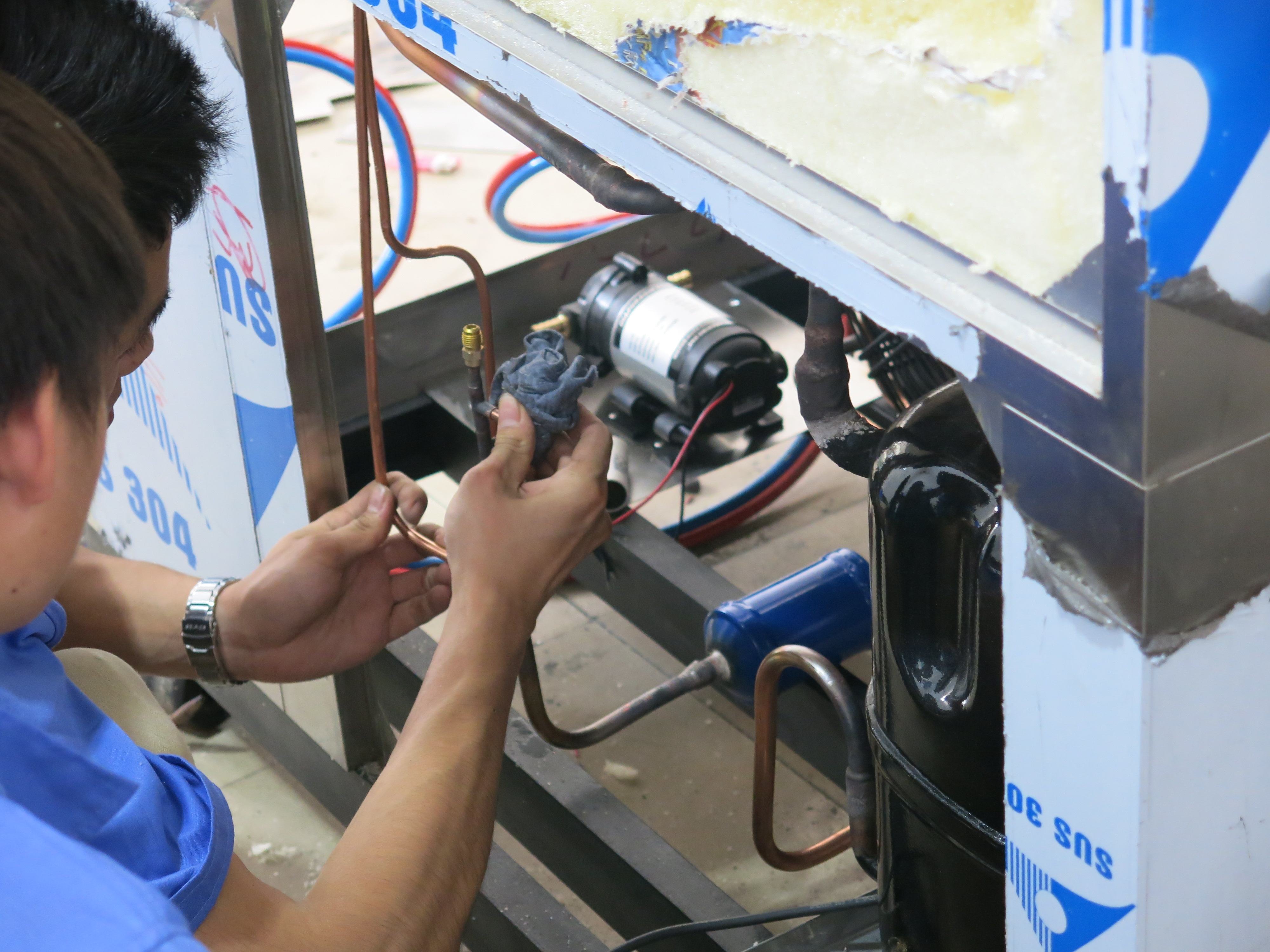

Common Failures in Humid Regions

Heater or steam generator scaling from hard water.

Piping blockage caused by mold or algae.

Sensor drift due to prolonged high-moisture exposure.

Recommended Replacement Schedule

| Part | Suggested Replacement | Notes |

|---|---|---|

| Humidity Sensor | Every 12 months | Prone to drift in tropical humidity |

| Water Filter Cartridge | Every 3 months | Especially with high mineral content water |