ASTM B117 Salt Spray (Neutral Salt Fog): What Matters and Why

What is the method for

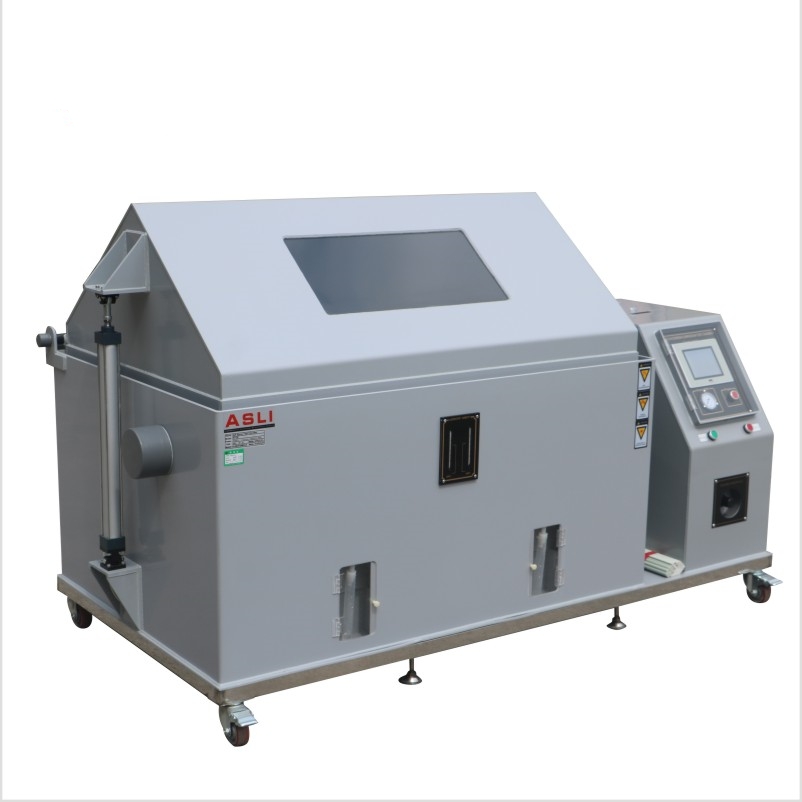

ASTM B117 defines how to run a neutral salt spray exposure so different labs can produce comparable results. It sets the apparatus, solution, and chamber conditions. It does not set pass/fail hours—performance criteria come from your product spec or drawing.

Where it’s used

Bare metals, plated fasteners, conversion coatings, and painted panels. Typical goals: compare pretreatments, rank coatings, screen process changes, or support qualification packages.

Test Conditions at a Glance

Temperature: chamber air is typically controlled around 35 °C as specified by the standard.

Solution: 5 % NaCl in deionized water, atomized into a fine fog.

pH: kept in a neutral range (~6.5–7.2); adjust with HCl/NaOH as needed.

Deposition/collection: verify the condensate fall-out rate is within the range the standard requires at the specified locations.

Controls & records: log chamber temperature, solution pH, and collection rate; inspect nozzles and filters; use clean tubing and reservoirs to avoid contamination.

Why it matters: Drift in pH, temperature, or fall-out rate can swing results more than the coating difference you’re trying to measure.

How Long Should You Run B117?

ASTM B117 doesn’t prescribe duration. Exposure time is set by your spec, often in tiers like 24/96/240/480/1000 h. Two reminders engineers keep repeating:

Comparative, not predictive: salt spray is great for ranking systems under a single, aggressive mechanism; it’s not a direct predictor of field life.

Define the endpoint: “no red rust,” “creep from scribe ≤ X mm,” or blistering ratings—state exactly what constitutes a failure.

ASTM B117 vs ISO 9227 vs ASTM G85

ISO 9227 (NSS): the neutral salt spray procedure in ISO is widely accepted globally; conditions are closely aligned with B117. Many exporters cite ISO 9227 for international programs.

ASTM G85 (modified fog): variants (e.g., acetic acid salt spray, copper-accelerated tests, cyclic procedures) introduce more aggressive chemistries or sequences when your use case demands it.

Takeaway: choose the procedure that best represents your failure mode and compliance landscape, not the one with the biggest hour count.

Specifying B117 on a Drawing or Test Plan

When corrosion requirements are left vague, you get arguments later. Nail down the details up front:

Substrate: alloy, temper, surface finish (e.g., Ra), cleanliness standard.

Coating system: chemistry, thickness range, cure/bake, sealers, conversion steps.

Edges & features: masking, radius, hole treatment, scribe method (if any).

Panel orientation & spacing: angle, distance from fog nozzles, drip avoidance.

Exposure: total hours and intermediate inspections (e.g., 96 h intervals).

Acceptance criteria: red rust vs white corrosion, blister ratings, creepage at scribe, or weight loss for bare metals; reference your evaluation method.

Replicates: number of panels per condition to control variability.

Well-written specs save time, samples, and re-tests.

Reading and Using Results

Painted/coated panels: track time to first red rust, blister size/frequency, and creepage from a scribe line; document with photos at fixed intervals.

Plated parts: distinguish white corrosion (zinc) from red rust (steel); define what counts as a failure area.

Bare metals: mass loss (cleaned per procedure) plus visual condition.

Trend, don’t cherry-pick: a single outlier panel is less informative than a median across replicates with process capability notes.

Common Pitfalls That Skew B117

Neutral pH drifting acidic/alkaline.

Salt solution made with tap water (chloramines, hardness contamination).

Panels touching or shadowing each other; pooling from horizontal surfaces.

Edges left sharp and unmasked when the spec assumes radius/mask.

Mixing panels from different pretreatment lots and treating them as replicates.

Control the basics; your coating comparison suddenly becomes meaningful.

Quick Answers Engineers Ask

How many hours equal “good” corrosion resistance?

There’s no universal number. “Good” is whatever your spec defines for your system under your risks. Many commodity coatings cite 96–240 h for screening; automotive/industrial coatings may target 480–1000 h with explicit failure criteria.

Is B117 enough for harsh service?

Often it’s the first gate. For marine/chemical exposure or complex cycles, move to ASTM G85 variants or add cyclic corrosion tests specified by your industry.

Can I compare my 240 h result to a competitor’s 1000 h claim?

Only if specimen prep, acceptance criteria, and chamber controls are equivalent. Otherwise, you’re comparing different tests.

Minimal Checklist Before You Start

Fresh 5 % NaCl solution, documented pH before/after atomization.

Chamber verified at ~35 °C with deposition rate in range.

Panel preparation and scribe method are defined and repeatable.

Exposure time and pass/fail language are written on the test plan.

Camera, scale, and forms are ready for interval inspections.