Understanding ASTM G154, ASTM G155, and ISO 4892 Weathering Test Standards

Why Accelerated Weathering Standards Matter

In product qualification and material durability testing, accelerated weathering standards are widely applied to evaluate how plastics, coatings, and other exposed materials will perform over time. Among the most frequently referenced are ASTM G154, ASTM G155, and ISO 4892. Although all three aim to simulate outdoor exposure, their test principles and applications differ in important ways.

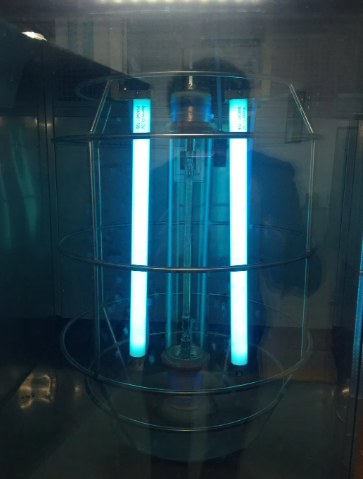

ASTM G154 – Fluorescent UV Lamp Testing

ASTM G154 is based on fluorescent UV lamps, typically UVA-340 or UVB-313. These lamps generate ultraviolet radiation only, without visible or infrared light. The main purpose is to accelerate photo-degradation caused by short-wave UV energy. Test cycles usually combine UV exposure with moisture through condensation or water spray. Because of the relatively low equipment and operating costs, this method is widely used for preliminary screening of plastics, coatings, rubbers, packaging materials, and construction products. However, since the light spectrum is not a full match with natural sunlight, results can be conservative or limited to surface changes.

ASTM G155 – Xenon Arc Lamp Testing

ASTM G155 specifies xenon arc lamp systems, which provide a broad spectrum of light that includes UV, visible, and infrared. In practice, this makes xenon testing much closer to natural sunlight, particularly for outdoor products. Test conditions may combine light with controlled humidity, water spray, or temperature cycles. The method is commonly applied in the automotive industry, outdoor plastics, architectural coatings, and textiles. The trade-off is that xenon chambers are more expensive and require more frequent maintenance, but they deliver results that better reflect real-world weathering.

ISO 4892 – International Framework

ISO 4892 is the international counterpart, with multiple parts covering both xenon arc and fluorescent UV lamp methods. The flexibility allows laboratories to align test conditions with regional or industry-specific requirements. For manufacturers targeting global markets, ISO 4892 is often requested because it carries broader recognition than ASTM alone. It also facilitates comparison between European and North American test practices.

How to Choose the Right Standard

From a practical standpoint, the choice of standard depends on both the product type and the end-use environment. If the aim is a rapid and cost-effective screening of basic UV resistance, ASTM G154 provides sufficient data. When durability under full-spectrum sunlight exposure is critical, especially for exterior automotive or construction applications, ASTM G155 is usually the preferred option. ISO 4892 becomes essential when customers or regulatory frameworks demand international harmonization, or when products are exported to multiple regions.

Key Takeaway for Manufacturers

In summary, ASTM G154, ASTM G155, and ISO 4892 are not competing standards but complementary approaches. G154 is efficient and economical for initial evaluations, G155 gives the most realistic outdoor simulation, and ISO 4892 ensures global acceptance. For laboratories and manufacturers, understanding these differences helps in selecting the right test method, balancing accuracy, cost, and market requirements.